From Chaos to Clarity: How Digital Twins Revolutionized ITC’s Asset Management

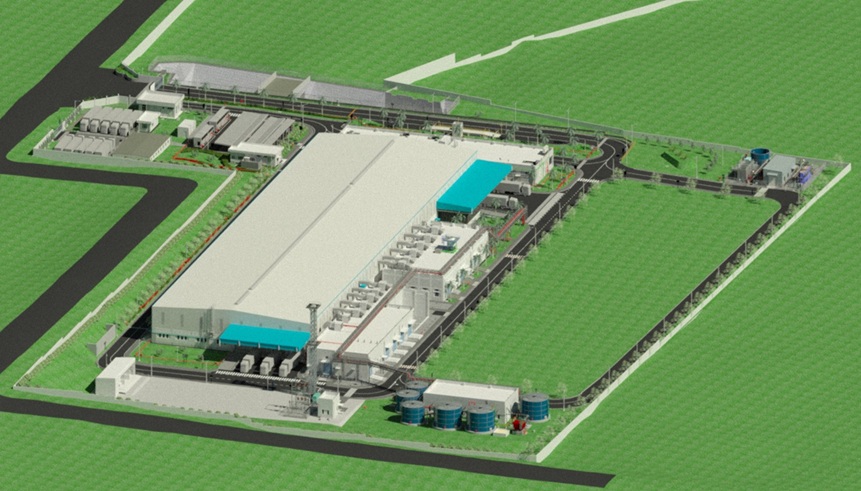

From GFC to As-Built: TRISITA Engineering’s Model Conversion for ITC’s Facility Management.

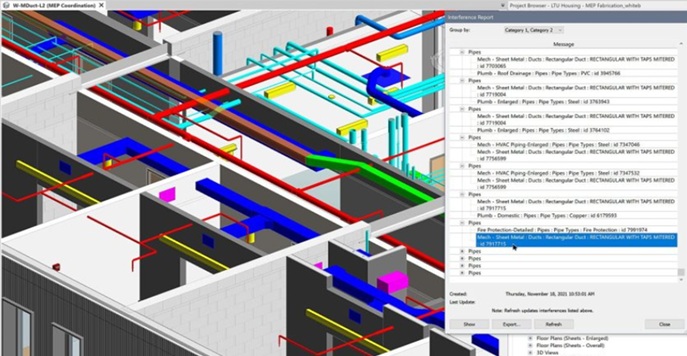

With as-built drawings not available, the Team stepped in to digitize and streamline ITC’s structure, architecture, and MEP system using Autodesk Revit and Autodesk Construction Cloud. The result? A powerful, accessible asset management system that future-proofs maintenance and operations.

May 20, 2025 6 mins read

- Digitized an entire facility with no existing as-built drawings, creating accurate BIM model from scratch.

- Reduced manual asset tracking by 85% with centralized, ACC-hosted data.

- Enabled virtual walkthroughs with high-quality renderings.