A BIM-generated interior rendering showcasing a recreational office space with designated zones

To tackle this, the Team adopted a Building Information modelling (BIM)-first approach. At the heart of the workflow was Autodesk Revit, used to develop a detailed, data-rich interior model. Every aspect — from MEP systems and wall layouts to furniture and finishes — was modelled to specification. Navisworks was then used to run clash detection simulations, ensuring that structural, architectural, and MEP systems coordinated flawlessly. This process uncovered potential conflicts early, saving valuable time and reducing the risk of costly site rework. Simultaneously, Autodesk Assemble enabled the extraction of accurate Bills of Quantities (BOQs) directly from the Revit model.

This helped in:

- Real-time quantity take-

- Streamlined procurement

- Budget control through live model-data

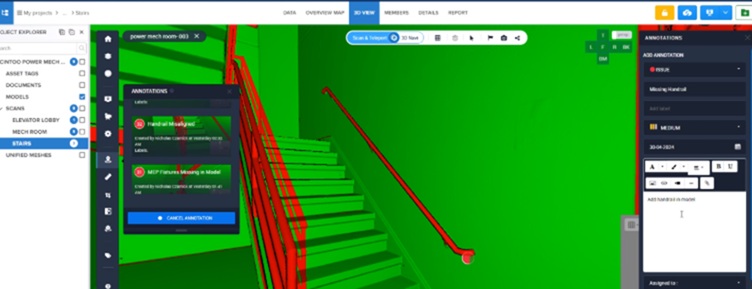

To unify collaboration, Autodesk Construction Cloud (ACC) acted as the central hub. All design documentation, model versions, and stakeholder comments were managed through ACC’s common data environment, ensuring transparency, version control, and faster decision-making.

The Execution: Model to Site with Confidence

Turning the vision into reality required precision, coordination, and the right set of digital tools. To ensure a smooth transition from concept to completion, the team leveraged the full power of Autodesk’s technology ecosystem, enabling end-to-end control over every phase of the project—from design to delivery. The journey began with Autodesk Revit, where the team developed a detailed, information-rich interior model that served as the foundation for all subsequent decisions. Using Navisworks, TRISITA conducted thorough clash detection to ensure seamless alignment of services, walls, and furniture. Autodesk Assemble enabled accurate BOQ extraction from the model, supporting real-time material tracking and budget control. All project documentation and collaboration were streamlined through AEC Document Management, ensuring version control and smooth coordination among stakeholders. With the Autodesk suite powering each phase, TRISITA ensured a frictionless journey from model to execution. The process allowed ITC’s internal teams to:

- Visualize and verify every design detail using the Revit

- Coordinate multi-disciplinary inputs using

- Monitor progress and quantities via Autodesk

- Maintain real-time communication across teams via Autodesk Construction