Virtual Reality in Construction: Transforming the Industry

As technology continues to evolve, industries across the board are harnessing the power of innovation to enhance efficiency, improve safety, and drive collaboration. One of the most exciting advancements in recent years is the integration of Virtual Reality in Construction sector.

Enhanced Visualization

One of the most significant advantages of virtual reality in construction is its ability to create immersive 3D environments. Architects, engineers, and clients can step inside a virtual model of a project long before it breaks ground. This enhanced visualization allows stakeholders to:

- Identify Design Flaws: Early detection of potential issues reduces costly changes during construction.

- Make Informed Decisions: Clients can better understand the project scope, leading to more informed feedback and choices.

Improved Collaboration

Construction projects often involve multiple teams working together. VR can bridge the communication gap by providing a shared virtual space where everyone can collaborate in real-time, regardless of their physical location. This leads to:

- Streamlined Communication: Stakeholders can discuss design elements and changes while experiencing the model together.

- Faster Decision-Making: Real-time collaboration speeds up approvals and consensus, keeping projects on schedule.

Enhanced Training and Safety

Safety is paramount in construction, and VR offers innovative training solutions that can significantly reduce workplace accidents. By simulating real-life scenarios, workers can:

- Practice Safety Protocols: Trainees can navigate potentially hazardous situations in a controlled environment, enhancing their preparedness.

- Learn Equipment Operation: VR can provide hands-on experience with machinery without the risks associated with real equipment.

Cost Efficiency

Whereas the introductory speculation in VR innovation can be considerable, the long-term investment funds are essential. VR helps in:

- Reducing Change Orders: By visualizing the project before construction begins, the likelihood of costly changes during the build decreases.

- Minimizing Waste: Better planning and communication lead to fewer mistakes and less material waste.

Client Engagement

VR offers a unique way to engage clients throughout the construction process. Instead of relying solely on blueprints and 2D plans, clients can:

- Experience the Space: Virtual walkthroughs provide a realistic sense of scale and design, helping clients envision the final product.

- Provide Feedback: Clients can interact with the design, making it easier to convey their preferences and suggestions.

Future Trends

The adoption of virtual reality in construction is just beginning, and several trends are emerging:

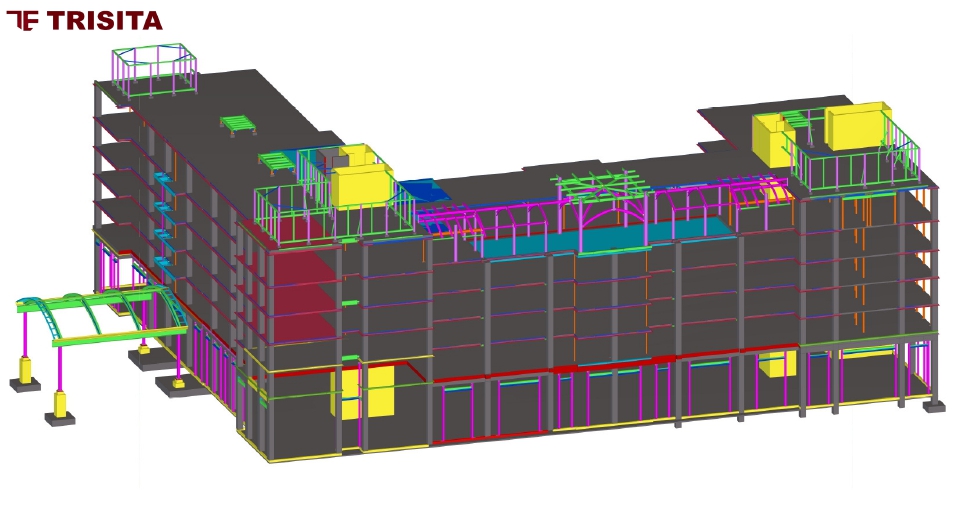

- Integration with Other Technologies: Combining VR with augmented reality (AR) and building information modeling (BIM) will create even more robust tools for construction management.

- Remote Collaboration: As remote work becomes more common, VR will facilitate ongoing collaboration among distributed teams.

- Customization and Personalization: As VR technology advances, it will become easier to tailor experiences to individual client needs, enhancing satisfaction.

Conclusion

Virtual Reality is not just a futuristic concept; it’s a game-changer for the construction industry. By improving visualization, collaboration, safety training, and client engagement, VR is paving the way for more efficient, safer, and more innovative construction practices. As technology continues to advance, embracing VR could become essential for companies looking to stay competitive in a rapidly evolving market.

Mastering Structural Steel Fabrication Drawings

Introduction

Structural steel fabrication drawings are the blueprints that guide the creation of steel structures, from skyscrapers to bridges. Understanding these drawings is crucial for anyone involved in the construction or manufacturing of steel components. This blog will delve into the key elements of structural steel fabrication drawings, providing insights for both beginners and experienced professionals.

Key Components of Structural Steel Fabrication Drawings

- Title Block: Contains essential information like the project name, drawing number, scale, date, and the names of the designer and checker.

- Revision History: Records any changes made to the drawing, including the date, revision number, and description of the modification.

- Views: Different perspectives of the structure, such as plan, elevation, and section views, to provide a comprehensive understanding of its geometry.

- Dimensions: Measurements of various components, including lengths, widths, and thicknesses.

- Material Specifications: Details about the type of steel used, its grade, and any special treatments or coatings required.

- Tolerances: Acceptable deviations from the specified dimensions to ensure proper fit and function.

- Symbols and Abbreviations: Standardized symbols and abbreviations used to represent different elements and features.

- Notes: Additional instructions or clarifications that may not be adequately conveyed through the drawings alone.

Types of Structural Steel Fabrication Drawings

- General Arrangement Drawings: Provide an overall view of the structure, showing the relationship between different components.

- Detail Drawings: Focus on specific components, providing detailed information about their dimensions, materials, and fabrication methods.

- Shop Drawings: Generated by the fabricator, these drawings show how the components will be assembled and connected.

- Erection Drawings: Guide the installation of the structure on-site, indicating the sequence of assembly and any special equipment required.

Tips for Reading Structural Steel Fabrication Drawings

- Start with the General Arrangement Drawing: Get a broad understanding of the structure’s layout before delving into the details.

- Use the Title Block and Revision History: Verify that you are working with the latest version of the drawing.

- Pay Attention to Dimensions and Tolerances: Ensure that components will fit together correctly.

- Consult the Notes and Symbols: Clarify any uncertainties or unfamiliar elements.

- Use a Drawing Scale: Accurately measure dimensions.

Conclusion

Mastering structural steel fabrication drawings is essential for anyone involved in the design, fabrication, or construction of steel structures. By understanding the key components, types, and reading tips outlined in this blog, you can effectively interpret these technical documents and contribute to successful projects.

Overview of Our Steel Services

We the TRISITA Team provides the cost-effective and quality service definitely helps companies not only to bid profitably but to deliver quality service to customers.

Let’s look at the specific advantages of outsourcing Steel Detailing Services:

-

Quality Drawings:

Structural steel may be used for homes, industrial buildings, bridges, and more. The detailing services require in-depth drawings. If you don’t have anyone on your team that understands how to use 2D and 3D drawing software properly.

-

Time Savings:

It can be time consuming to create the various drawings and details.

Instead of spending all of that labour, you can outsource and let a professional company provide you with all of the services that you need.

-

Cost Savings:

The cost savings can be significant. You won’t have to hire an

engineer and invest in CAD software if you choose to outsource. This will ensure your needs are met without having to hire someone for services that you may only

need periodically.

-

Better Reporting:

One of the first benefit is that you will be able to get better

reporting. There are a variety of reports that can be created when premier software is used. This includes material summaries, gather sheets, and more. It will ensure that everyone is on the same page. It will also allow those within fabrication to know exactly what needs to be created while those in finance will be able to attach a value to it for budgeting purposes.

-

More Convenient Information:

The information that you received from a third party can ensure that the Tekla steel detailing is available when and where you need it the most.

-

Quality Tools:

Finally, more tools will be available at your fingertips. The drawings can be integrated into a variety of systems. These will be used not only by the fabrication shops but also by facility managers once the project has been completed. The more drawings and detailing you have, the easier it will be to keep everyone in the know.

In today’s dynamic and fast-paced construction industry, fabricators are racing to complete their work as they are faced with tighter construction schedules and have longer material lead times. Nowadays, steel fabrication shop drawing can be taken care of with different types of advanced detailing software thus saving time and money.

Hope this helps you in understanding Trisita’s Steel Setailing Services. Find out more about our services and products on our latest blog page.