The construction industry is embracing digital transformation at an exceptional pace, and one of the most exciting improvements main this modification is Digital Twin Technology in construction. From designing and constructing buildings to coping with their ongoing operations, digital twins offer an effective device that complements decision-making, will increase efficiency, and improves sustainability. But what precisely is a virtual dual, and the way is it reshaping the destiny of production? Let’s discover.

What is a Digital Twin?

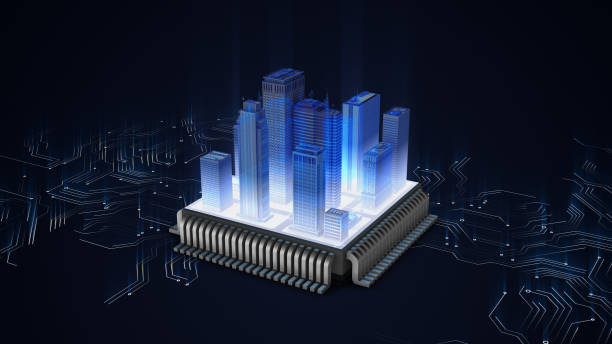

A digital twin is a digital sign that refers to a physical object, device, or method. Operationally, the digital twin is a deep, interactive 3D model of a building or infrastructure-related project that continuously generates new real-time computations from sensors, IoT devices, and other components.

Think of it as a resident blueprint—one that is not just the initial plan but evolves as it progresses or even after the plan ends.

How Digital Twin Technology is Changing Construction

1. Optimizing the Design and Planning Process

The design phase of a creation challenge sets the tone for the entirety that follows. With digital twin technology in Construction, designers and engineers can create noticeably unique, interactive 3-D fashions of the constructing before construction begins. These fashions offer a complete view of the structure, incorporating architectural info, engineering specifications, and even actual-global situations like environmental elements or structural loads.

Using Digital Twin Technology in construction, groups can run simulations and stress tests to see how the building will carry out underneath numerous situations, supporting perceive capacity layout flaws before any physical work begins. This now not handiest quickens the layout procedure but also minimizes the risk of errors, transform, and high-priced revisions as soon as construction is underway.

2. Enhancing Real-Time Project Management

Managing a production assignment isn’t any small feat. With countless responsibilities, stakeholders, and substances to coordinate, it’s easy for delays or miscommunications to derail the assignment. Digital twin generation permits construction managers to display every element of the construct in real time, from materials and gadget to exertions productivity.

By integrating sensors and IoT devices into the construction site, a virtual dual can provide non-stop information on progress, allowing undertaking managers to tune whether the assignment is on agenda, inside budget, and aligned with the design. This real-time feedback facilitates discover issues early, allowing quicker changes and decreasing the probability of luxurious delays or errors.

3. Predictive Maintenance and Long-Term Building Management

Once a building is finished, its management becomes just as crucial as its production. Digital twins offer excellent value in the operational phase of a building by means of imparting ongoing tracking and renovation insights. With sensors embedded within the shape, virtual twins can music the overall performance of structures consisting of HVAC, electric, plumbing, and lights in actual time.

This non-stop tracking allows constructing managers to anticipate while device will want upkeep or replacements, providing predictive protection abilities. By addressing problems before they amplify into major disasters, digital twins can make bigger the life of constructing systems and reduce long-time period renovation prices.

Additionally, facility managers can use the statistics from the virtual dual to optimize the building’s electricity intake, improving efficiency and sustainability. For example, the device might alert managers to inefficient HVAC settings, or help optimize lighting fixtures schedules based totally on occupancy styles, in the long run lowering power cost.

4. Boosting Collaboration Across Teams

In any huge-scale creation assignment, coordination between multiple teams—architects, engineers, contractors, and clients—is crucial. Digital twins provide a significant, shared version that each one stakeholder can access and engage with in real time. This guarantees that everyone is operating with the equal records, helping to save you misunderstandings, conflicts, or miscommunications.

With actual-time updates and easy access to records, teams can collaborate greater effectively, make choices quicker, and resolve troubles earlier than they become fundamental problems. For example, if there’s a warfare between the structural design and the electric format, the digital dual can spotlight the discrepancy, allowing the team to solve it earlier than construction starts off evolved.

5. Sustainability and Environmental Impact

As sustainability will become a developing difficulty inside the production industry, virtual twins are playing an essential function in supporting homes reap extra energy efficiency and reduce their carbon footprint. By simulating the building’s power use below exceptional eventualities, digital twins assist architects and engineer’s layout systems which are optimized for power efficiency and sustainability.

Once the constructing is operational, the virtual dual continues to offer precious insights into power intake, water usage, and waste management. This information can help building owners become aware of areas for development, which include adjusting heating and cooling systems to reduce power consumption or figuring out leaks which can result in water waste.

The Future of Digital Twin Technology in Construction

As the development industry keeps to include virtual innovation, the function of digital twins will only continue to grow. The integration of emerging technology like synthetic intelligence (AI), machine mastering, and augmented truth (AR) will decorate the abilities of virtual twins even similarly.

For example, AI algorithms can analyze vast quantities of facts generated via digital twins to are expecting destiny building performance, presenting even extra insights into capability issues before they stand up. Similarly, AR era can permit construction employees to overlay digital models onto bodily process websites, offering actual-time steerage and ensuring that construction is done to the highest standards.

In the long term, digital twins will now not only revolutionize the way homes are designed, built, and controlled however can also play a imperative function in developing smarter, more sustainable cities. By growing virtual twins of entire urban environments, cities can optimize everything from site visitors go with the flow and waste management to power distribution and public safety.

Overcoming Challenges in Implementing Digital Twins

While virtual twins provide considerable benefits, their implementation can gift demanding situations. Creating and preserving a virtual twin requires great investment in each generation and training. The in advance expenses of installing sensors, gathering records, and developing the virtual model can be high, in particular for smaller initiatives or organizations.

Additionally, managing and analyzing the data generated by means of digital twins requires specialized understanding and abilities. To fully recognize the potential of virtual twins, construction teams have to invest within the proper tools and expertise.

Data safety is some other situation. As greater homes and infrastructure come to be connected, making sure that the massive amounts of records generated by virtual twins are blanketed from cyber threats is important. Implementing sturdy cybersecurity measures may be critical to retaining the integrity of Digital Twin Technology in construction.

Conclusion

Digital Twin Technology in construction is converting the face of production, supplying effective gear to decorate layout, streamline mission control, and improve building performance. As the technology evolves and will become more integrated with different innovations like AI, system studying, and AR, its impact on the construction industry will best develop.

For production corporations trying to stay in advance of the curve, adopting virtual dual technology is now not only a trend—it’s a strategic move closer to smarter, more efficient, and extra sustainable construction practices. Whether you are designing a new constructing, optimizing a present one, or handling a whole metropolis, digital twins are the key to unlocking the future of production .