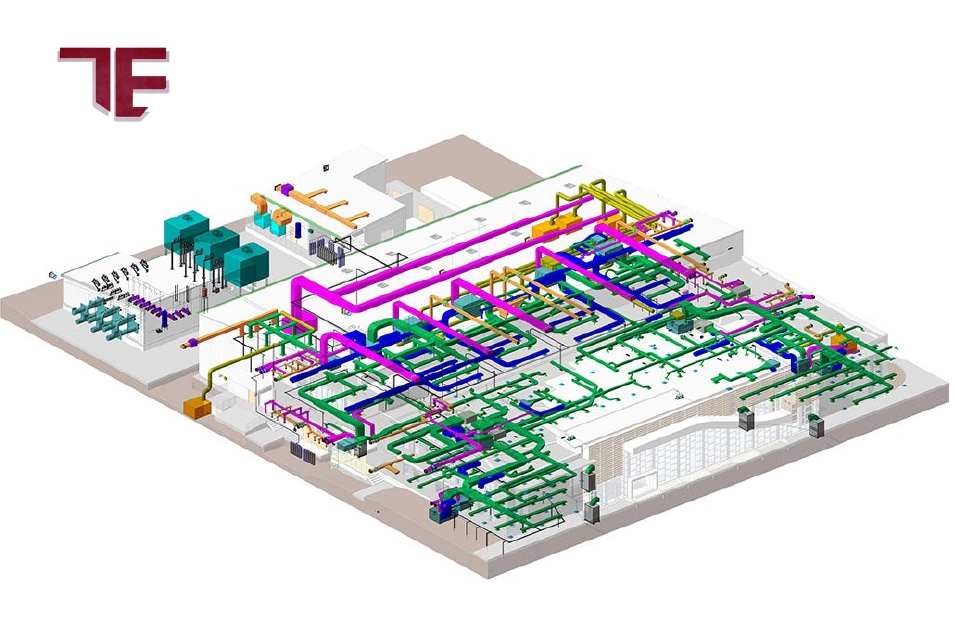

MEP drawings in construction are specialized illustrations that are essential for construction and structure design. Among the colourful specialized drawings involved, MEP(Mechanical, Electrical, and Plumbing) drawings stand out as pivotal documents that insure the effective integration of vital structure systems.

What Are MEP drawings?

MEP drawings are detailed plates that illustrate the layout and specifications of a building’s mechanical, electrical, and plumbing systems. These drawings serve as a design for architects, engineers, and contractors, detailing how each system will be designed, installed, and integrated into the overall structure.

Importance of MEP Drawings

- Facilitating Coordination: MEP systems often occupy limited space within walls, ceilings, and floors. Well-prepared MEP drawings help coordinate these systems, minimizing conflicts and ensuring that installations proceed smoothly.

- Enhancing Efficiency: MEP drawings must cleave to original structure canons and regulations. They enable better planning, resource allocation, and scheduling, ultimately saving time and reducing costs associated with errors or rework.

- Supporting Maintenance: MEP drawings in construction serve as vital resources for facility management teams, aiding in the ongoing maintenance, troubleshooting, and potential upgrades of the building’s systems.

Key Components of MEP Drawings

Mechanical Drawings:

- HVAC Systems : These drawings detail the heating, ventilation, and air exertion systems, including conduit layouts, outfit locales, and tailwind patterns.

- Fire Protection Systems : This includes details on fire admonitions, sprinkler systems, and exigency exit routes.

Electrical Drawings:

- Lighting and Power Layouts : These plates outline the placement of electrical outlets, switches, lighting institutions, and main power sources.

- Wiring plates : Detailed schematics showing circuit connections and electrical loads are pivotal for both installation and troubleshooting.

Plumbing Drawings:

- Water Supply and Drainage : These layouts include pipeline systems, institution locales, and waste disposal styles.

- Gas Line Installations: Drawings may also encompass layouts for gas lines that supply heating and cooking appliances.

Best Practices for Creating MEP Drawings

- Utilize Building Information Modeling (BIM): Incorporating BIM technology enhances the accuracy and efficiency of MEP designs.It allows for real- time collaboration among all stakeholders and helps identify implicit issues beforehand on.

- Maintain Regular Updates : MEP drawings should be continuously streamlined throughout the design lifecycle to reflect any changes or variations.

- Encourage Collaboration: Foster open communication among architects, engineers, and contractors. Regular meetings can address challenges proactively and ensure that everyone is on the same page.

- apply Quality Control : Establish a thorough review process for MEP drawings. Peer reviews can catch crimes beforehand and insure compliance with assiduity norms.

- Adhere to Standardization: Using standardized symbols and conventions enhances clarity, making it easier for all team members to understand the drawings.

Conclusion

MEP drawings in construction are an essential element of systems, furnishing the necessary information for the successful integration of mechanical, electrical, and plumbing systems. By understanding their significance and clinging to stylish practices, construction professionals can enhance collaboration, ameliorate compliance, and streamline design prosecution. Investing in high- quality MEP drawings not only supports immediate design success but also lays the root for effective structure operation and conservation in the long term. Embrace the significance of MEP drawings and insure your construction systems thrive!