ITC operates across diverse industries such as FMCG, hospitality, paperboards, and construction. For this particular project, they aimed to execute a portable construction site, requiring each structure to be divisible into smaller, transportable modules — without compromising integrity or design coherence.

The core challenge? Figuring out how to split the entire structure into transportable segments while maintaining coordination across architectural, structural, MEPF (Mechanical, Electrical, Plumbing, and Firefighting) systems. The task demanded more than just design, it needed advanced planning, error-free documentation, and seamless multi-disciplinary integration.

TRISITA’s Tailored Approach: BIM for Modular Mastery

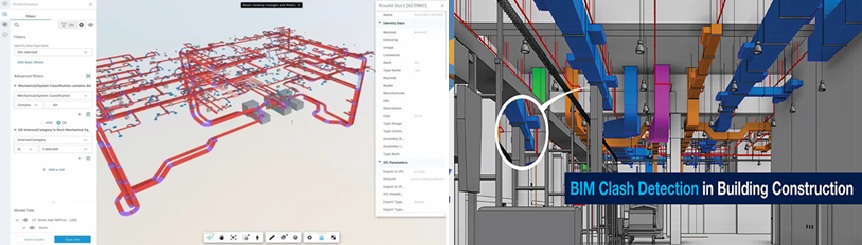

TRISITA Engineering recognized that a robust BIM strategy was crucial to address ITC’s portability challenge. Their approach centered on creating a comprehensive digital model of the entire structure using Autodesk Revit. This intelligent model served as the central source of information, allowing for detailed design, clash detection, and the generation of precise fabrication drawings. breaking down the complex structure into manageable components within the Revit environment. This meticulous segmentation allowed for the independent design and detailing of each module while ensuring seamless integration during final assembly. TRISITA’s team worked closely with ITC, maintaining open communication and incorporating their specific requirements at every stage of the modelling process.

Tools & Technology: Leveraging Autodesk Solutions

Autodesk Revit was at the heart of the operation. TRISITA created a unified model incorporating architectural, structural, and MEP systems. From this, they extracted:

- GFC (Good for Construction) drawings

- General Arrangement (GA) drawings

- Intra-module drawings

Each output played a vital role in preparing the structure for its portable nature.

To manage documentation efficiently, TRISITA deployed Autodesk Construction Cloud, enabling real-time access to documents, version control, and streamlined communication between ITC’s teams and on-site contractors. Navisworks was used to aggregate and review the models, helping detect potential clashes early and validate the overall assembly for construction.