From Concept to Cumin: TRISITA Builds ITC’s Future Spice Factory

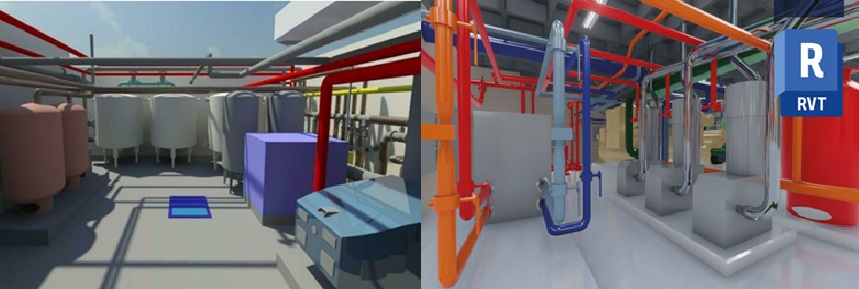

From digital design to 4D simulation, precision met planning at every step.

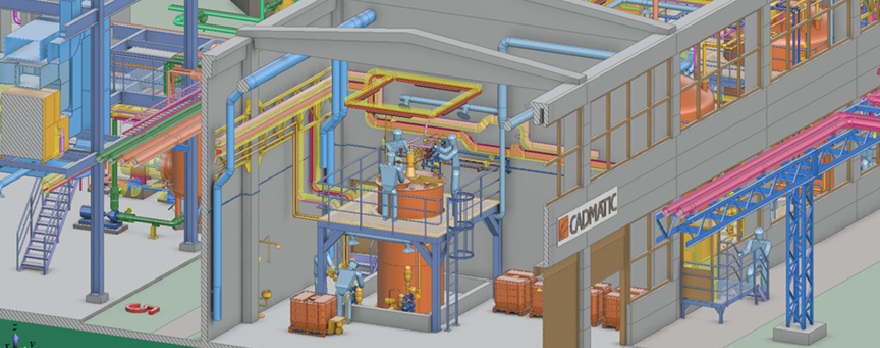

Discover how TRISITA Engineering helped ITC’s proposed spice processing factory come to life—virtually—before a single brick was laid. We leveraged advanced BIM and 4D simulation to streamline ITC’s spice processing plant design, eliminating costly clashes and optimizing logistics before construction began.

May 20, 2025 6 mins read

- 30% reduction in on-site clashes through pre-construction clash detection.

- 1.5–2 year timeline simulated and optimized using 4D BIM.

- Fully animated logistics simulation showcasing truck movement, pedestrian flow, and plant operations.